1. Pain points of plane laser cutting machine

1.1 on the market, most of them use single laser, and use

manual feeding and unloading, resulting in low efficiency of actual cutting.

1.2 the actual effect of most brands on the market tends to be

the same, with weak competitiveness and serious homogenization.

1.3 single function of machine tool, low bargaining power.

2. Introduction of cooperative manufacturers

A company in

Dongguan, the current cooperation model is 3015 three head laser synchronous

cutting equipment. The feature of the scheme is that the single bus controller

controls three laser heads at the same time, supplemented by the online cutting

function, with good synchronization.

At present, the price of

medium and small power laser is dropping by half at the rate of 18 months. The

efficiency of medium and small power single head cutting machine tool has

basically reached the bottleneck. If the equipment manufacturers want to expand

the sales volume of equipment, they must configure equipment with differential

function. On the basis of a certain laser power, it is necessary to increase

the laser head power.

There

are two original schemes for customers: one is the plane cutting machine with

simple single laser head, with positioning accuracy of ± 0.05mm and repeated

positioning accuracy of ± 0.03mm; the second is to control the three laser

heads with three sets of numerical control systems, with complex control and

poor synchronization.

After

using the scheme of Tsino Dynatron, the customer directly uses a set of

controller to control the simultaneous operation of three laser heads. The

operation is simple. The cost of the customer's machine tool is reduced by tens

of thousands yuan, the positioning accuracy is ± 0.03mm, the repeated

positioning accuracy is ± 0.015mm, the air moving speed is 50M / min, and the

efficiency is at least 80% higher than the original scheme.

4. Characteristics

of controller and driver in multi head cutting scheme

4.1 Controller——ROBOX Controller

1) Online cutting function, through controlling

the linear speed of rack, matching the online speed tracking of laser cutting

head, online cutting is realized.

2) Multi head cutting, controlling multiple laser

heads to cut on line at the same time, the efficiency is doubled, the safety

range is set, the cutting safety is guaranteed, the equipment downtime is reduced,

and the cutting efficiency is increased.

4.2 Servo Drive ——CoolDrive S7

1) The response of current control is

high, the current update time is only 2.5us, and the 16

bit current sampling accuracy.

2) The

speed loop has high frequency response, up to 3kHz, which can realize high

dynamic response.

3) Support

on-line self-tuning, servo debugging process is simple, technical requirements

for customers are reduced.

4) Gantry

synchronization, the driver has its own special gantry synchronization

interface, through the bottom hardware real-time interactive information, the Real time of synchronization control is better than through the

upper computer to control the gantry synchronization.

5) Quadrant

protrusion suppression and other vibration suppression functions can reduce the

vibration at the end of the laser head, improve the cutting accuracy and

efficiency.

6) The

drive information is Easy to view and the device status information can be read

directly from the OLED display screen of the device.

7) Bluetooth

debugging function, S7 can connect with intelligent terminal through Bluetooth,

quickly check the status of the device, real-time debugging, fault analysis and

processing, so that the operation becomes simpler and more intelligent.

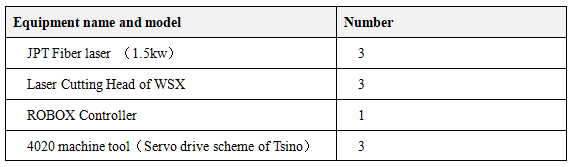

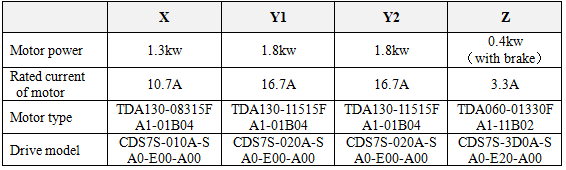

5. Multi laser head

servo electrical configuration

6. Concluding remarks

For

the multi head gantry laser cutting machine, there is no room for further

improvement in the common pulse control mode, and the synchronization, accuracy

and processing efficiency have gradually reached the bottleneck. And the

high-performance servo system like CoolDrive S7, which supports EtherCAT bus

communication, is very suitable for high demand application scenarios such as

laser cutting machine tools.